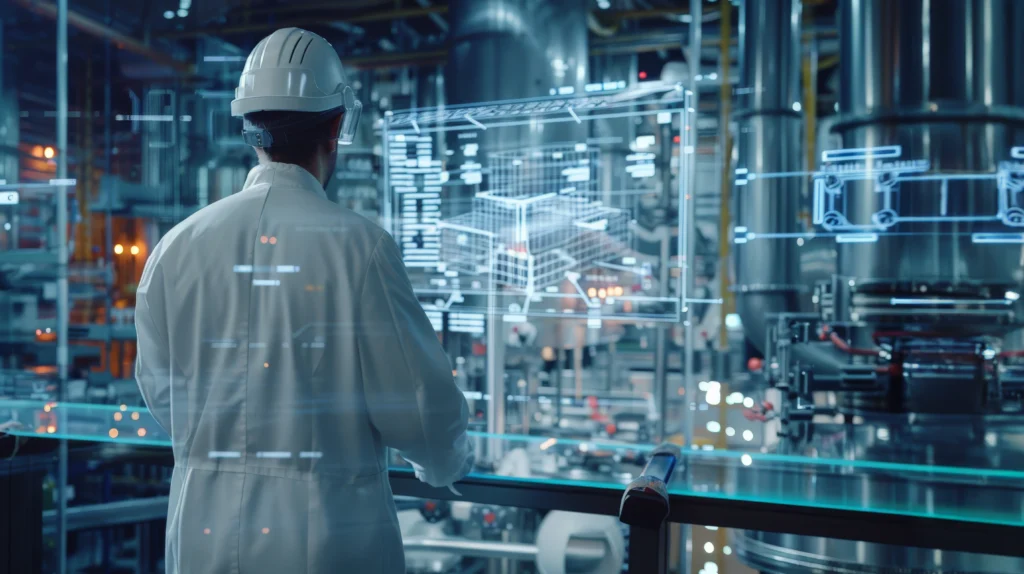

Industrial Automation and Control Systems: Driving the Future of Industry

In today’s rapidly evolving industrial landscape, automation and control systems have become the backbone of modern manufacturing, energy, and infrastructure operations. They ensure efficiency, reliability, and safety while reducing costs and enabling real-time decision-making. This blog dives deep into Industrial Automation and Control Systems (IACS)—what they are, how they work, their benefits, and the trends shaping their future.

1. What Are Industrial Automation and Control Systems?

Industrial Automation and Control Systems (IACS) refer to the integrated hardware, software, and communication technologies used to monitor and control industrial processes. These systems automate repetitive tasks, regulate machinery, and provide real-time insights into operations.

Broadly, IACS consists of:

- Programmable Logic Controllers (PLCs): Rugged digital computers used to control manufacturing processes.

- Distributed Control Systems (DCS): Systems that spread control across multiple nodes for large-scale, continuous processes (like oil refineries).

- Supervisory Control and Data Acquisition (SCADA): Systems that collect and analyze real-time data, often across geographically dispersed sites.

- Human-Machine Interfaces (HMIs): Interfaces that allow operators to monitor and control systems visually.

Together, these components form the nervous system of modern industrial operations.

2. Importance of Industrial Automation

- Efficiency and Productivity

Automated systems work 24/7 without fatigue, ensuring higher throughput and consistency compared to manual operations. - Quality Control

With precise control over processes, automation reduces human error and ensures uniform product quality. - Safety

By taking humans out of hazardous environments, automation minimizes workplace accidents. - Cost Savings

Reduced labor costs, minimized downtime, and optimized resource use result in long-term savings. - Data-Driven Insights: Real-time monitoring enables predictive maintenance, reducing unexpected breakdowns.

3. Key Components of IACS

1. Sensors and Actuators

- Sensors measure physical parameters like temperature, pressure, or flow.

- Actuators convert signals into actions (e.g., opening valves, starting motors).

2. Controllers

- PLCs and DCS execute pre-programmed logic to control machinery and processes.

3. Communication Networks

- Industrial protocols such as Modbus, Profibus, and Ethernet/IP ensure seamless data exchange between devices.

4. Supervisory Systems

SCADA and HMIs provide visualization, alarms, and centralized monitoring.

Challenges in IACS

While automation brings immense value, it also faces challenges:

- Cybersecurity Threats: As IACS becomes more connected, they are increasingly vulnerable to cyberattacks.

- High Initial Investment: Setting up automation systems requires significant capital.

- Skilled Workforce Shortage: Operating and maintaining advanced systems requires specialized skills.

System Integration Complexity: Integrating legacy systems with modern technologies can be difficult.

4. Future Trends in Industrial Automation

- Industry 4.0 and Smart Factories

Integration of IoT, AI, and machine learning to create self-optimizing, data-driven factories. - Edge and Cloud Computing

Real-time decision-making at the edge, with cloud storage and analytics for long-term insights. - Collaborative Robots (Cobots)

Robots designed to safely work alongside humans, enhancing flexibility in operations. - Digital Twins

Virtual replicas of physical systems that allow simulation, testing, and predictive analysis. - Green Automation

Focus on energy efficiency and sustainable manufacturing processes.

Conclusion

Industrial Automation and Control Systems are transforming industries by making operations smarter, safer, and more efficient. As the world moves toward Industry 4.0, IACS will play a pivotal role in shaping the future of manufacturing, energy, and infrastructure. Businesses that embrace these technologies today will be better positioned to thrive in the competitive, data-driven world of tomorrow.

For further reading on similar topics, check out article on : How Maritime Autonomous Surface Ships Are Changing the Future of Shipping

-

Learning Marine Automation: Skills That Power Modern Ships

Learning Marine Automation: Skills That Power Modern Ships -

Industrial Automation Solutions for Modern Manufacturing Industries

Industrial Automation Solutions for Modern Manufacturing Industries -

Industrial Automation in Modern Industry

Industrial Automation in Modern Industry -

Industrial Automation Applications in Today’s Smart Factories

Industrial Automation Applications in Today’s Smart Factories -

Advanced Industrial Automation Systems: Transforming Modern Manufacturing

Advanced Industrial Automation Systems: Transforming Modern Manufacturing