Advanced Industrial Automation Systems: Transforming Modern Manufacturing

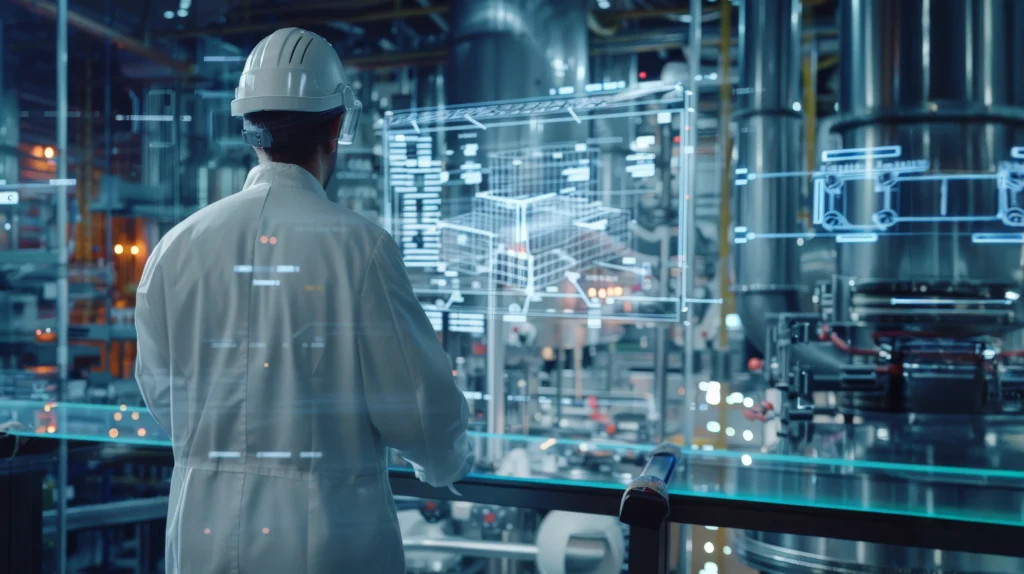

The rapid evolution of technology has pushed industries to adopt smarter, faster, and more efficient production methods. At the heart of this transformation are advanced industrial automation systems, which are reshaping manufacturing with intelligent machines, real-time monitoring, and data-driven decision-making.

What Are Advanced Industrial Automation Systems?

Advanced industrial automation systems use sophisticated technologies like AI, machine learning, and the Internet of Things (IoT) to automate complex tasks, rather than just simple repetitive ones.

They go beyond traditional automation by following:

Smart control

Early maintenance

Data insights

Accurate output

Smooth machine

Core Components of Advanced Industrial Automation Systems

- Programmable Logic Controllers (PLCs): The central unit that controls automated processes in real time.

- SCADA Platforms: Provide live monitoring, data logging, alarms, and control capabilities.

- Industrial Robotics: Robots handle tasks like welding, assembly, painting, and material handling with high precision.

- IoT & Smart Sensors: Enable continuous data flow for accurate decision-making.

- AI & Machine Learning: Analyze performance patterns, forecast failures, and optimize workflows.

Benefits of Advanced Industrial Automation Systems

1. Improved Productivity

Automation helps to reduces idle time and increases output respectively.

2. Enhanced Safety

Workers are protected from high-risk, repetitive, or hazardous tasks.

3. Consistent Product Quality

Advanced control systems prevent variability and human error.

4. Predictive Insights

Sensors and AI detect abnormalities before breakdowns occur.

5. Cost Optimization

Reduced waste, energy efficiency, and minimal downtime lower operational costs.

How Advanced Industrial Automation Systems Improve Overall Plant Performance

- Faster Production Cycles: With automated controls and smarter machines, factories can complete tasks much faster. Processes that once took hours can now be done in minutes, helping companies meet tight deadlines.

Better Use of Resources: Automation helps reduce unnecessary waste. Whether it’s raw material usage or energy consumption, advanced industrial automation systems ensure everything is used efficiently.

- Real-Time Monitoring for Quick Decisions: Operators can see what’s happening on the production floor at any moment. If a machine slows down or stops, the system alerts the team instantly, preventing long delays.

- Improved Worker Safety: By letting machines handle risky tasks, automation reduces workplace accidents. Workers can focus on supervision, quality checks, and skill-based tasks while machines handle the heavy work.

- Higher Product Consistency: One of the biggest advantages of advanced industrial automation systems is consistent quality. Whether it’s 100 units or 10,000 units, every product maintains the same standard.

The Future of Advanced Industrial Automation Systems

The future points toward smarter, more connected, and more autonomous systems.

Some key trends include:

AI-powered autonomous factories

Digital twin technology for virtual testing

Robotics-as-a-service (RaaS)

Cloud-integrated automation

Human–robot collaborative workspaces

These innovations will redefine global industrial standards.

Conclusion

Advanced industrial automation systems are the driving force behind Industry 4.0. As industries demand higher speed, accuracy, and flexibility, these systems will continue to evolve, enabling smarter, greener, and more efficient manufacturing worldwide.

For further reading on similar topics, check out article on: When Machines Think: The Rise of Smart Industrial Automation

-

Advanced Industrial Automation Systems: Transforming Modern Manufacturing

Advanced Industrial Automation Systems: Transforming Modern Manufacturing -

When Machines Think: The Rise of Smart Industrial Automation

When Machines Think: The Rise of Smart Industrial Automation -

The Next Frontier in Marine Automation: Autonomous Vessels

The Next Frontier in Marine Automation: Autonomous Vessels -

Industrial Automation and Control Systems: Driving the Future of Industry

Industrial Automation and Control Systems: Driving the Future of Industry -

Global Autonomous Ships Market Expected to Grow 30% by 2028

Global Autonomous Ships Market Expected to Grow 30% by 2028